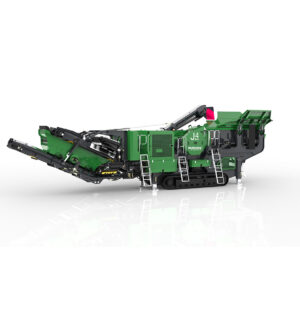

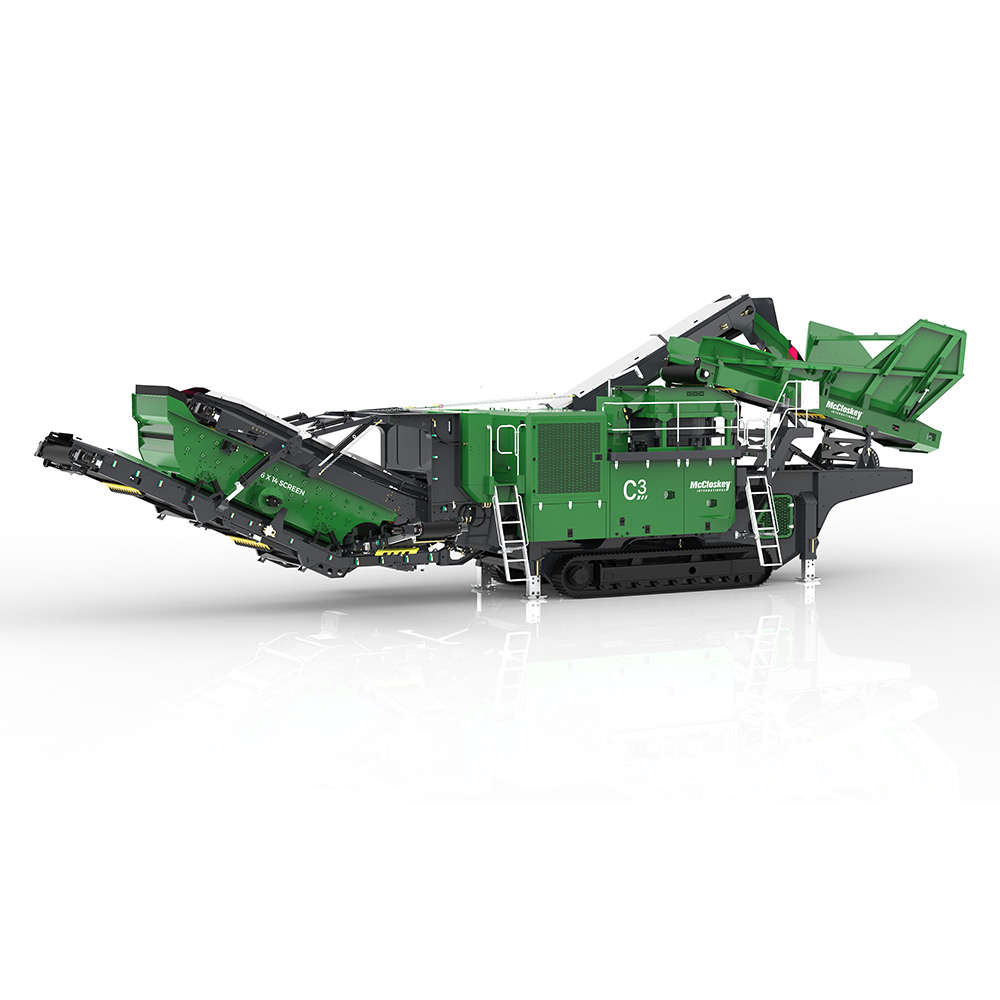

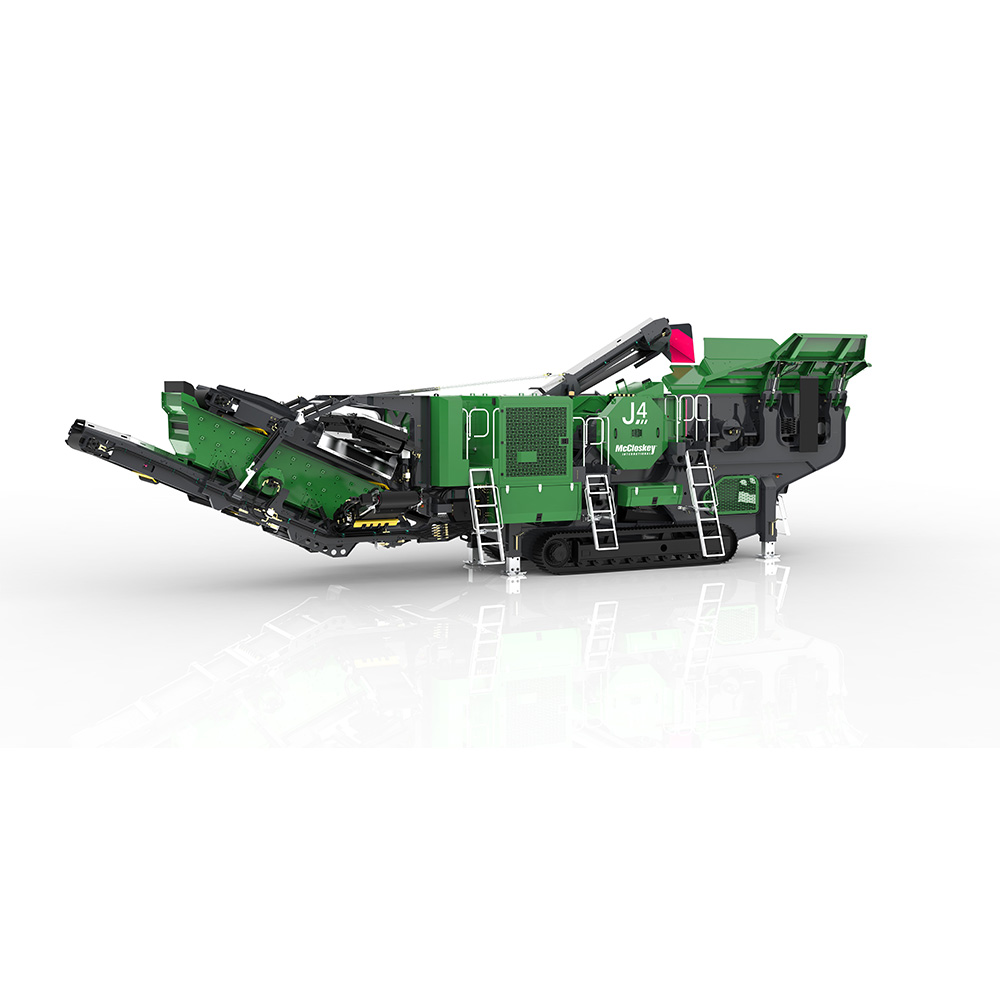

Standard features are far from standard on the new McCloskey® compact and portable C2C cone crusher, including unrivalled ground level access, full-size MC200 cone, powerful engine, efficient conveyor design, and continuous load and material monitoring. McCloskey mobile cone crushers have been designed to deliver superior performance while also achieving high capacity, better product quality, optimum versatility and improved fuel efficiency

- Overview

- Technical Info

- Download PDF

McCloskey C2C

- 280 (375 Hp)kw Engine

- 2.65m Transport Width

- 31,680kg Weight

- Cone

- Feeder

- Conveyor

The McCloskey C2C Cone Crusher is the ideal portable secondary crushing solution for operators requiring production rates up to 300 TPH. Its unrestricted feed opening improves material feed intake and reduces the risk of blockage. The direct drive cone on the C2C has a minimum setting of 13mm (0.5”) and a maximum feed of 185mm (7.28”). The variable speed of the crusher delivers the best combination of production and product shape, maximizing its efficiency in crushing.

Intellegent level sensor controlled feeder with large Hardox lined hopper having a capacity of 5 cubic meters.

Features a wide main conveyor at 1200mm with an adjustable stockpile height of up to 3.3m.